Ex-proof General Knowledge

Explosion-proof enclosures are solid cabinets that contain different electrical components like switches, plugs, sockets, transformers, controls, and knobs to keep the surroundings safe from electrical hazards. Integrated with sound technology, these boxes are resistant to spark and shock and have a high tolerance to extreme temperatures. An ideal solution for hazardous locations; these explosion-proof enclosures keep any interior explosion from spreading to the external environment and damaging life and property.

Applications of explosion-proof enclosures

Explosion-proof enclosures are available in different shapes, sizes, and specifications for different applications. These spark resistant units house electrical equipment and ensure complete safety of surroundings. Typical applications include:

Petroleum refineries

Industries using flammable liquids for operations

Petrochemical industries

Dry cleaning plants

Fuel servicing areas

Gas plants

Feed mills

Plants running metallurgical processes

Chemical plants

Producers of plastics and fireworks

Producers of medicines, sugar plants, and candies

Carbon-handling units

Textile mills

Flax processing plants

Choosing enclosures for industrial applications

With more and more companies going green, electronic products are now being designed for use in turbines, solar power systems and alternative energy systems that run with the aid of power and employ smart grids. Faulty installations can lead to fatal injuries and accidents. With the increasing need for electronics in every industry, it is important to consider these five points when selecting enclosures for specific applications:

Location

Where the product will be installed determines the level of protection needed. Wind turbines are installed outdoors due to which they need to meet NEMA specifications for which 4X enclosures need to be installed. It is important to determine which enclosure has the required strength and durability to protect the equipment from dripping water, powerful sprays, dirt, dust, snow, sleet and debris depending on the location of installation.

Capabilities

The capacity of your chosen enclosure plays a vital role in maintaining safety and speeding installation. The availability of brackets and attachments can be a huge help. It is important to have a mounting panel when installing a variety of electric components. Standard enclosures are readily available and cost much less as compared to customized units.

NEMA/RFI Ratings

Applications that involve monitoring and consolidation of excess power from different sources require added protection. A die-cast enclosure made from aluminum with a double layering of gaskets and an outer gasket for sealing the moisture makes an ideal solution for such applications.

Dimensions

Apart from environmental safety, you should also consider the future needs of your industry. The scope and extent of expansion play a decisive role in determining the dimensions of the enclosure. A small enclosure may prove to be an excellent space saver but can invite significant expenses in the long run. Enclosure modifications for cable access also need to be taken into consideration in enclosure selection.

Design

The appearance of the enclosure becomes particularly important when it is being installed in a home or an office. The material of the enclosure also needs to be selected depending on the end-use. Installing an industrial unit for controlling a domestic solar system is not a sound choice. A plastic unit with a sleek design makes a perfect solution for residential installations.

References:

Categories: Electrical engineering Electrical safety Explosion protection

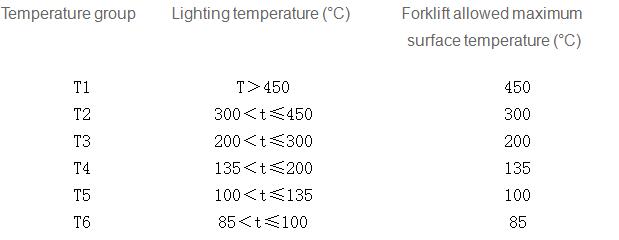

|

Name |

Burning point (°C) |

Temperature group |

Explosion level |

Name |

Burning point (°C) |

Temperature group |

Explosion level |

|

Acetone |

540 |

T1 |

IIA |

Acetylene |

305 |

T2 |

IIC |

|

Acetic anhydride |

330 |

T2 |

IIA |

Benzene |

555 |

T1 |

IIA |

|

Butane |

365 |

T2 |

IIA |

N-butanol |

340 |

T2 |

IIA |

|

Phenyl chloride |

590 |

T1 |

IIA |

Ethanol |

425 |

T2 |

IIA |

|

Acetic acid |

460 |

T1 |

IIA |

Methanol |

455 |

T1 |

IIA |

|

Nitrobenzene |

430 |

T1 |

IIA |

N-pentane |

285 |

T3 |

IIA |

|

Propane |

470 |

T1 |

IIA |

Toluene |

535 |

T1 |

IIA |

|

Hydrogen |

560 |

T1 |

IIC |

Hydrogen sulfide |

270 |

T3 |

IIB |

|

Carbon disulfide |

102 |

T5 |

IIC |

Vinyl |

450 |

T2 |

IIB |